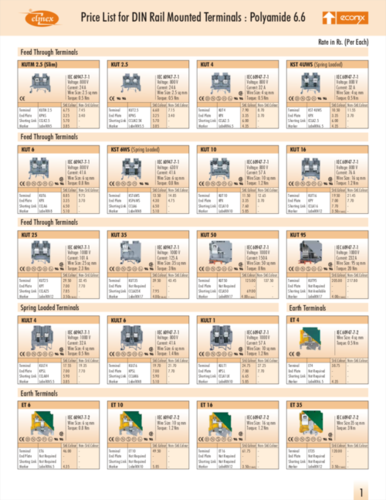

Product Description

Earth Terminals are essential components designed to ensure reliable grounding and electrical safety in various applications. Constructed from high-quality, corrosion-resistant materials, these terminals facilitate effective grounding connections, minimizing the risk of electrical faults and enhancing system stability. Their user-friendly design allows for easy installation and secure attachment to a wide range of equipment, making them suitable for both commercial and residential projects. With robust performance and compliance with industry standards, Earth Terminals provide peace of mind by safeguarding against electrical surges and ensuring compliance with safety regulations. Whether for use in electrical panels, machinery, or telecommunications, these terminals are a critical part of any grounding strategy.

High Conductivity and SafetyManufactured from brass/copper alloy with electroplated or zinc-plated surface finish, these earth terminals provide excellent electrical conductivity and robust corrosion resistance. Flame class V2 (UL94), halogen-free insulation, and Class I protection elevate safety standards, making them suitable for demanding environments.

Versatile Application and Easy InstallationThe terminals support both DIN rail and panel mounting, with screw type connections and double wire entry for flexible wiring options. Designed for single-phase systems up to 415 V, they accommodate conductor sizes from 0.5 mm to 10 mm, making them useful for a broad range of earthing processes in electrical installations.

Compliance and Environmental ProtectionThese earth terminals comply with IEC 60947, RoHS, and UL94 V2 flame resistance standards, ensuring environmental safety and electrical reliability. The polyamide (PA 6.6) insulation is halogen-free, contributing to safer operation and meeting high humidity resistance up to 95% RH.

FAQs of Earth Terminals:

Q: How do Earth Terminals support safe electrical grounding?

A: Earth Terminals facilitate secure earthing connections by providing a high-conductivity pathway that minimizes electrical resistance and prevents faulty circuits. Their corrosion-resistant brass/copper alloy construction and Class I protection ensure reliable long-term safety.

Q: What is the recommended process for installing these earth terminals?

A: These terminals are designed for quick installation on DIN rails or panels. After stripping the cable to the proper length, insert the conductor into the double wire entry and tighten the screw clamp to a torque of 0.6 Nm for a secure connection.

Q: When should I use these terminals in an electrical setup?

A: It is ideal to use these earth terminals when constructing or upgrading grounding systems, particularly in industrial, commercial, or residential projects that require compliance with IEC 60947 and RoHS standards and demand vibration resistance and flame retardancy.

Q: Where can these earth terminals be mounted?

A: The terminals offer versatile mounting options and can be installed on DIN rails or directly onto electrical panels, making them suitable for various environments and configurations.

Q: What are the benefits of using polyamide insulation in these terminals?

A: Polyamide (PA 6.6) insulation provides flame resistance (V2 class), halogen-free protection, high durability, and the ability to operate effectively in environments with up to 95% relative humidity, enhancing operational safety.

Q: How does double wire entry improve usage flexibility?

A: Double entry allows for easy connection of two separate conductors, speeding up the wiring process and supporting more complex earthing configurations without extra hardware.

Q: Are these earth terminals suitable for high-temperature environments?

A: Yes, they are designed for storage temperatures ranging from -40C to +90C and operating temperatures from -25C to +85C, making them suitable for a wide range of ambient conditions.